AUTOMOTIVE

Carbinite’s expertise is in providing coating technology to various industries. Carbinite’s founder, Rob Freyvogel, is a high-performance automobile enthusiast. From autocross to drag racing to road racing to land speed racing, Rob has designed, modified, and built cars that push the limits. Understanding that even the smallest variable can make a difference, he developed metal coating solutions that can improve automobile performance both on and off the track.

Supercharger Pulleys

Effective immediately, Carbinite no longer provides supercharger coating service for anyone other than distributors.

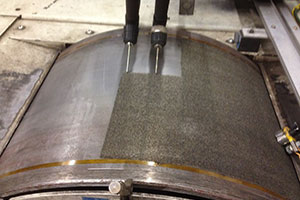

Chassis Dyno Applications for Carbinite

Couple a high HP car with worn knurls on a chassis dyno, and wheel spin can become a major problem leading to inaccurate results and safety hazards. Applying Carbinite’s traction enhancement textured coating to your worn chassis dyno drums can eliminate wheel spin, improve traction, and increase the precision of your readings.

Carbinite’s Dyno Drum Refurbishing coating is a cost and time-efficient alternative to thermal sprays or dyno drum reknurling. Carbinite can be applied on-site (within the continental United States) without drum removal to minimize your downtime. Drums do not need to be rebalanced after coating. Carbinite’s grade 3.5 coating is optimized for high-horsepower cars.

Our Carbinite coating is a long-lasting hardened material, metallurgically bonded to your chassis dyno drum. It is guaranteed to not crack, chip, or peel. It is usually a more cost-effective and time-efficient solution to worn drums than drum replacement.

We’re sorry, but we’re unable to accommodate international dyno customers at this time. Please click the button below and we will keep your information for when we are able to travel internationally.