MEDICAL INDUSTRY

As with any industry that requires tight tolerances and precision manufacturing, it is important in the medical industry to have tools and devices with good holding power. Applying Carbinite’s textured metal coating to fixturing used with medical instruments or workholding used in medical manufacturing provides the needed grip without deforming or altering parts.

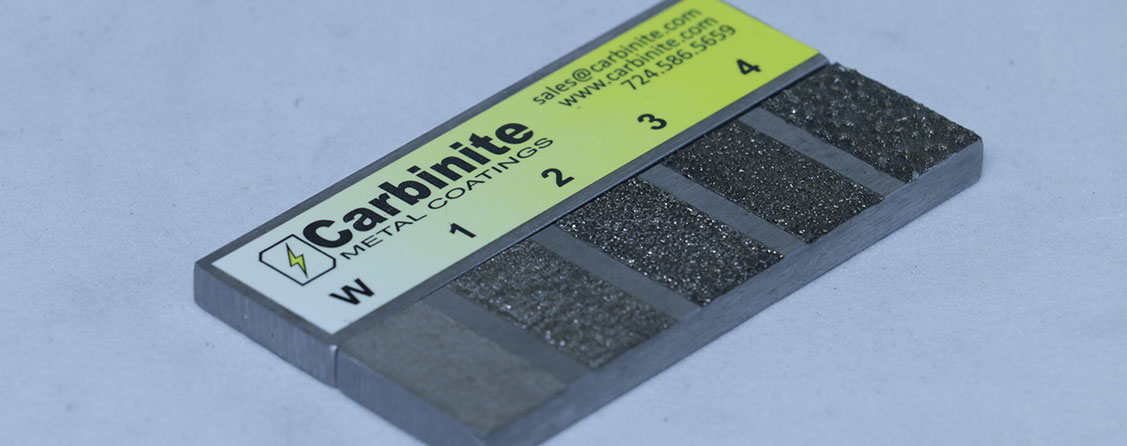

Carbinite is not a spray coating, allowing for precise application. Parts can be taped and coated by hand ensuring our coating is applied exactly where grip is needed. While all grades of Carbinite can be used in medical applications, many benefit from grades W through 2 which provide needed grip without marring the parts. The thickness and texture of each coating grade are controlled by the settings of our proprietary coating equipment, guaranteeing quality and uniform coating with every application.

Applications for Carbinite in the Medical Industry

Medical Manufacturing

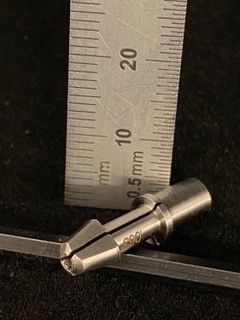

Our textured carbide-based coatings increase the coefficient of friction, allowing for more efficient operation and increasing the life expectancy of medical industry tools and equipment. Collets, jaws, and robot fingers last longer and hold parts more reliably during the manufacturing of medical instruments.

Medical Applications

Carbinite can be applied to fixturing used in the medical industry to reduce slipping while instruments are in use. Pins used in orthopedic braces can be coated with Carbinite, keeping the brace in place. Mounts, joints, and fixtures used with a variety of equipment can be coated with Carbinite, reducing slippage during examinations and procedures.

Carbinite is committed to research and development of new applications in the medical industry. Please contact us if you would like to discuss an idea that may benefit from Carbinite.