INDUSTRIES SERVED

- WORKHOLDING

- PRIMARY METALS

- SAFETY

- AUTOMOTIVE

- OIL & GAS

- MATERIALS HANDLING

PRIMARY METALS

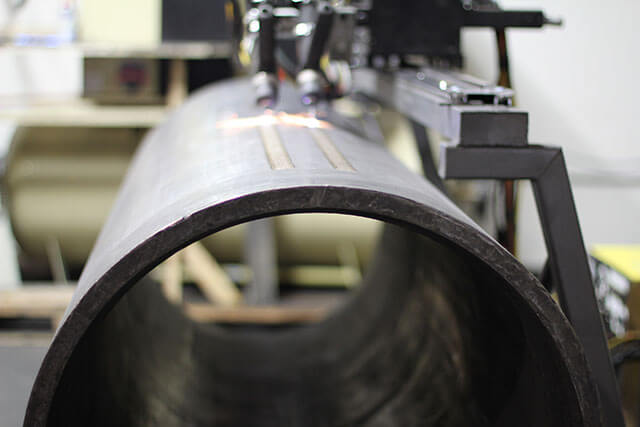

Carbinite offers a metallurgically bonded textured coating solution for mill applications such as spools and mandrels, often times replacing thermal spray and hard chroming.

Carbinite coatings are comprised of wear-resistant carbide alloys that increase grip to enhance mill performance. Utilizing a process called Electro Spark Deposition (ESD), Carbinite coatings display exceptional bond strength without annealing or distortion.

Carbinite’s applications for primary metals include applications in the forging industry which includes various manufacturing & workholding processes including the elimination of slippage

Our coating is guaranteed to not chip, flake, or peel. Carbinite can be applied or re-applied on-site by our experienced technicians to minimize your downtime.

Applications for Carbinite in Steel & Aluminum Mills

Our textured carbide-based coatings increase the coefficient of friction, allowing for more efficient operation and increasing the life expectancy of your equipment. Carbinite’s W coating is designed for wear resistance applications, or when a light grip is needed. Due to our unique ability to apply both smooth and textured coatings, we can give you the surface you need where you need it most. Applications in the steel and aluminum industry that have benefitted from our textured coatings include:

- Expanding mandrels

- Stub mandrels

- Coiling spools

- Steering rolls

- Bridle rolls

- Drive rolls

- Table rolls

- Pay-off reels

- Wire feed wheels

- Gripper wedges

- Downender pads

- Safety Flooring, Stair Edges, and Mill Rails

Benefits of Carbinite’s Coating

Some benefits of using Carbinite’s coating in the primary metals manufacturing industry include:

- Pulling tension earlier on mandrels, spools, and reels reduces processing time and improves mill output.

- Textured coating allows for better control of strip tension, eliminating slip and coil dumps.

- Carbinite’s W+ coating reduces or eliminates pick-ups and stickers on downender pads and other areas where aluminum transfer is an issue.

- On-site service is available to reduce mill downtime.

Custom Mandrel Inserts

Rolling harder and thicker clad stock in aluminum mills requires more extreme levels of tension which can lead to the spool slipping on stub mandrels, resulting in “coil dump.” Carbinite has developed a cost-effective solution to eliminate scrap, maximize production, and minimize downtime. Carbinite offers engineering and coating of custom mandrel inserts that decrease maintenance time and eliminate scrapped coils due to slippage.

Existing stub mandrel segments can be modified to accept custom A2 tool steel inserts coated with Carbinite. The A2 provides the ideal coating substrate to extend your mandrel service life, Carbinite provides the extra grip needed to eliminate coil or spool slip, and the quick-change inserts greatly reduce maintenance time needed to renew the clamping surfaces of your mandrel.