WORKHOLDING

Clamping and gripping various components for machining and fabricating can often be an overlooked variable in improving production and maximizing profits. Carbinite’s textured coatings increase the coefficient of friction, resulting in greater holding power for your workholding applications. This, in turn, allows for increased feed rates, optimized production efficiency, and extended tool life. Applying Carbinite’s unique carbide alloy coatings reduces or eliminates workholding slippage in machine tools and fabricating equipment used during the manufacturing process.

Carbinite is also an excellent application for primary metal-related processes including use in steel and aluminum mills.

Applications for Carbinite in Machining

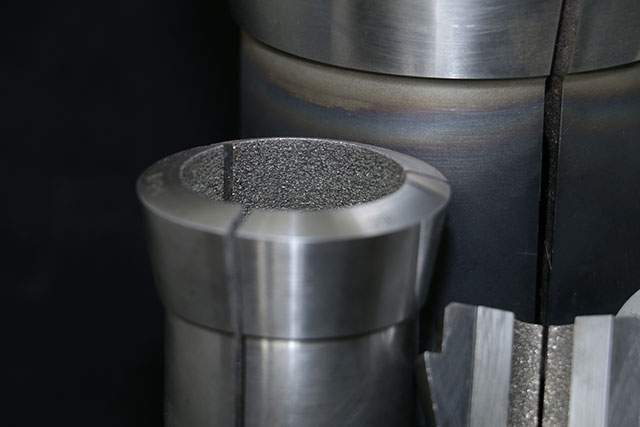

Collets

The principle of applying Carbinite to collets is that it allows the clamping surface to be keyed to the material with tiny peaks. We call this action Surface Microkeying. Carbinite coated collets make less noticeable marks than serrated collets. Carbinite coatings can be applied as hard as 70Rc adding life to your critical components. Swiss machines, lathes, screw machines, and others experience significantly less slippage when using tooling coated with Carbinite, such as:

- Collets

- ID Collets

- Collet Pads

- Pusher Pads

- Bar Pullers

- Expanding Mandrels

Jaws

Components made for clamping can benefit from Carbinite’s textured carbide coatings to decrease or eliminate slippage. In clamping tests, Carbinite has been shown to nearly double the gripping strength at equal clamping forces. Our customers see an increase in both grip and tooling life with clamping details coated with Carbinite, including:

- Vice Jaws

- Step Jaws

- Pie Jaws

- OD Grippers

- ID Grippers

- Gripper Fingers

Other Workholding

Carbinite can be applied to many other applications to eliminate part slippage during machining and fabricating operations.

- Custom Fixturing

- Key Holders

- Robot Jaws

- Robot Grippers

- Contact Pads

- Clamping Fingers

- Rest Pads

- Magnetic Chucks

- Pole Extensions

- Centers – including taper, dead, live, gage, grinding, drive, and more

Applications for Carbinite in Fabricating

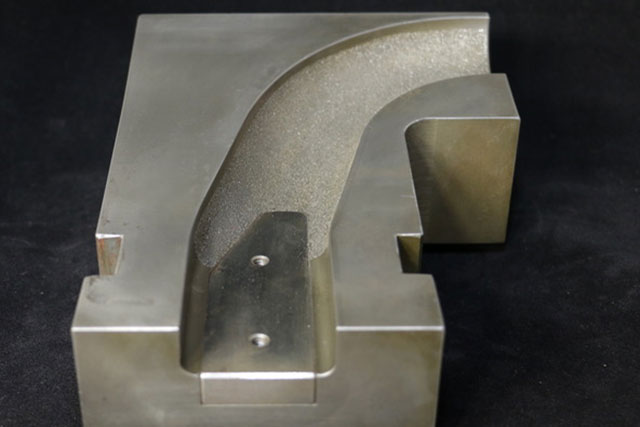

Tubing

A common problem with tube clamping is that since it is hollow, too much clamping pressure can collapse the tube. The application of Carbinite can prevent tubing from shifting in the die during bending and forming applications without excessive clamping pressure.

- Tubing Dies

- Tubing Die Inserts

- Tubing Die Clamps

- Flaring Dies

- End Forming Clamp Blocks

- Mandrel Bend Dies

- Rotary Draw Dies

Sheet Metal

Carbinite added to the jaws of your shrinker / stretcher will improve the tools efficiency and extend jaw life.